75/36 100% elastic yarn 20D Denier air-wrapped yarn: innovative technology improves fabric breathability

Jun 06,2025

Unraveling the Durability: Why Polyester Embroidery Thread Reigns Supreme

Jun 06,2025

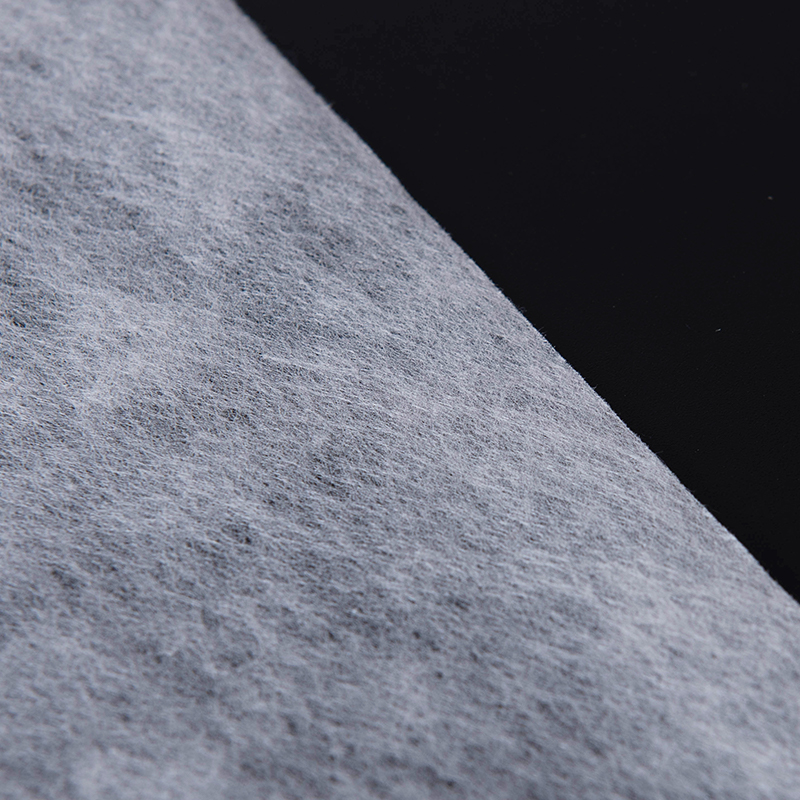

The power of nonwovens: how non-woven fabrics impact modern life

Jun 06,2025

From strength to protection: Nylon cable performance and selection guide for various applications

Jun 06,2025

Creative Ways to Incorporate Sequin Yarn into Clothing Designs for Stunning Visual Effects

Jun 06,2025

Why is Embroidered Non-Woven Fabric a cost-effective and versatile choice for fashion and home decor?

2023-04-19

What is Polyester Dope Dyed DTY Yarn?

2023-05-05Your email address will not be published. Required fields are marked *

facebook twitter dribbble instagram

*Indicates a required field

Copyright © Shaoxing Qiufei Textile Technology Co., Ltd.  Custom Embroidery Thread Yarn Manufacturers

Custom Embroidery Thread Yarn Manufacturers